The minster cfc 3 disc 28 brake clutch is a very strong and smart part used in big machines. It helps machines stop and start safely while they do heavy work like stamping or pressing metal. If you are someone who wants to learn how this part works, or maybe you are thinking of buying a used press, then this blog is just right for you. Many people feel confused when they hear these big words, but don’t worry—we will explain everything in a very simple way, step by step.

This blog will help you understand what the minster cfc 3 disc 28 brake clutch is, what it does inside a press machine, and why it’s important. We will also talk about how to take care of it and what things to check before buying one. So, let’s begin and learn together with easy words and helpful tips.

What Is the Minster CFC 3 Disc 28 Brake Clutch and How Does It Work?

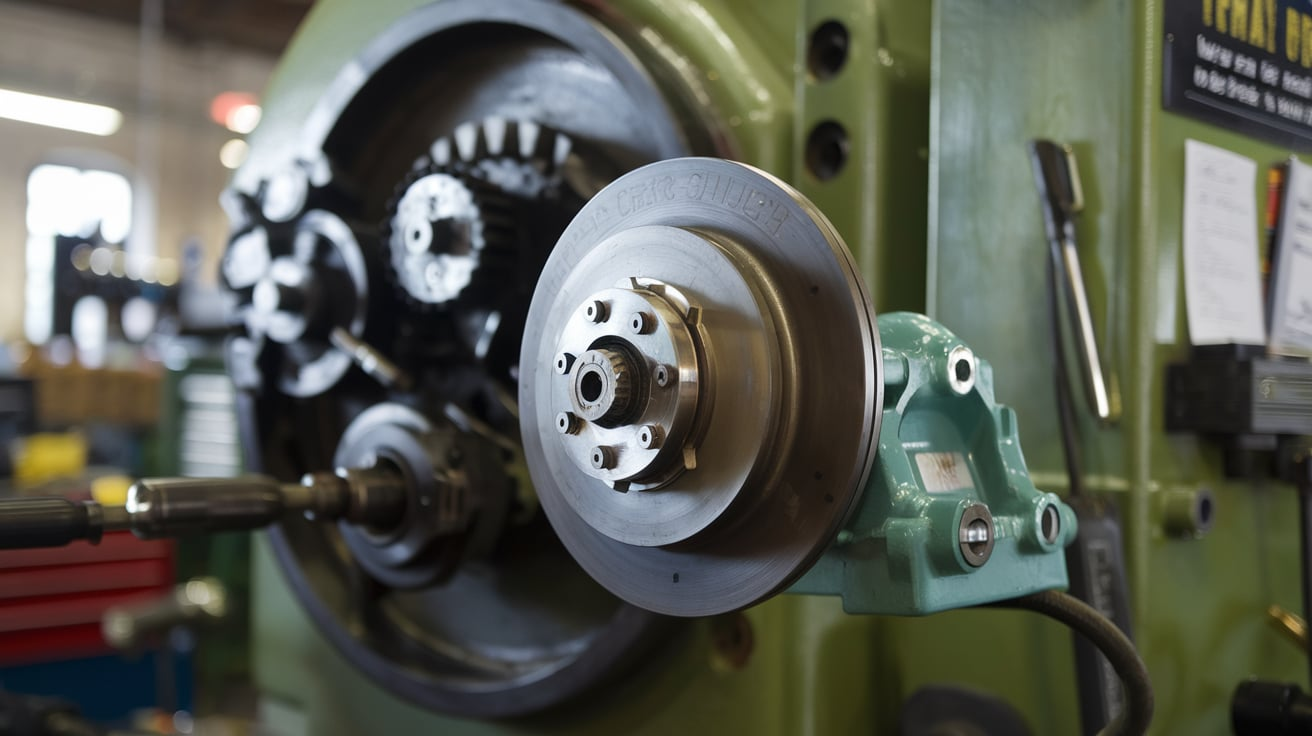

The minster cfc 3 disc 28 brake clutch is a special part that helps big press machines work smoothly. It has three strong discs inside that help the machine start and stop fast without shaking or breaking. This part connects to the crankshaft and helps control the motion. When the machine needs to press something hard, the clutch gives power. When it needs to stop, the brake works quickly to slow it down. This system is very safe and helps protect the whole machine. It is made by Minster, a company known for strong and smart machine parts. If the press works like a strong robot arm, this clutch and brake are like the brain and legs that help it move and stop. This part is made to handle heavy jobs all day long without getting too hot or tired.

Why the Minster CFC 3 Disc 28 Brake Clutch Is Still Trusted in Old Machines

The minster cfc 3 disc 28 brake clutch is still used today in many older machines because it was made to last a long time. Even after many years, it works well if it is taken care of. Factories like it because it is simple, strong, and easy to fix. This clutch doesn’t break often and when it does, you can find parts easily. It helps press machines keep working, even after many years. Some people even buy old machines just because they know this clutch is inside. This means it has a very good name. It’s also known for being very safe and smooth when working. That’s why sellers still list machines with this clutch in good condition, and buyers trust them. It’s like an old car engine that still runs great after years if you treat it right.

Simple Parts Breakdown of the Minster CFC 3 Disc 28 Brake Clutch

The minster cfc 3 disc 28 brake clutch has a few key parts that help it work the right way. The main parts are the three clutch discs, the brake pads, springs, and a shaft to connect everything. The three discs are made of strong metal and grip the machine tight to move it. The brake pads help slow down the machine quickly when needed. The springs push parts back in place after they move, so the machine doesn’t get stuck. There are also small oil holes to keep everything smooth and cool. All these parts are put together very carefully by Minster so the clutch and brake can work for a long time without needing too much fixing. If one part wears out, it can be changed easily. It’s built in a way that even older workers know how to fix it fast.

How to Check a Used Minster Press with CFC 3 Disc 28 Brake Clutch

Before buying a used press that has a minster cfc 3 disc 28 brake clutch, you should check a few things first. Look at the clutch and brake area and see if there is any oil leaking or broken metal. Try to listen to the sound when the machine runs—if it makes loud noises, something may be wrong inside. You should also ask the seller when it was last checked or fixed. See if the discs still look strong and not thin or burned. Check the springs too, because if they are weak, the machine won’t stop fast. It’s a good idea to see if the machine stops smoothly without shaking. You can ask for a test run to be sure. If everything works fine, then it’s a good machine. This part is the most important, so it’s okay to take your time to check it well.

Real Uses of Minster CFC 3 Disc 28 Brake Clutch in Press Machines

The minster cfc 3 disc 28 brake clutch is mostly used in metal stamping machines. These are big machines that press metal sheets into shapes like car parts, cans, and tools. The clutch helps the machine press very hard and the brake makes sure it stops right away after each press. It is used in places like car factories, tool shops, and packaging companies. Some presses use this clutch to make very tiny parts, while others make big items like doors or machine covers. Because it works fast and safe, many factories still use it today. It helps the machine press again and again without problems. People like this clutch because it gives power when needed and also protects the machine from breaking. It works like a safety helper and a power booster in one.

Beginner Tips: How to Care for a Minster CFC 3 Disc 28 Brake Clutch

Taking care of a minster cfc 3 disc 28 brake clutch is not very hard. First, keep it clean. Wipe off dirt and check for oil leaks often. You should check the discs every few months to make sure they’re not too thin or damaged. Always use the right kind of oil so the parts inside don’t get too hot. Don’t run the machine too fast for too long, or it can hurt the clutch. Listen to the sound of the press—if it starts making strange noise, stop and check. Also, don’t let the machine sit too long without use because it might get rusty. If something seems wrong, call someone who knows how to fix it. A little care can make the clutch last for many years and save money on big repairs later.

Signs Your Minster CFC 3 Disc 28 Brake Clutch Needs Repair

Sometimes the minster cfc 3 disc 28 brake clutch shows signs that it needs help. One sign is if the machine does not stop fast like it used to. Another sign is if it starts making loud sounds or if the press shakes while working. If you see smoke or burning smell, that’s a bad sign. Also, if the press feels slow or weak when pressing metal, the clutch could be slipping. You can also check the parts visually—if the discs look very thin or burnt, they need to be replaced. Oil leaks near the clutch area are another warning. It’s smart to check every few months so you can fix small problems before they get big. A good working clutch keeps the whole press safe and strong, so don’t wait too long to check it.

What Makes the Minster CFC 3 Disc 28 Brake Clutch Different from Other Clutches?

The minster cfc 3 disc 28 brake clutch is different because it has smart design and strong build. It has three discs which help it work better and faster than many other clutches. Most other clutches only have one or two discs, so they don’t last as long or stop as safely. This clutch was made by Minster, a company with over 100 years of machine-building experience. They made this part with safety, power, and long life in mind. It’s also easier to fix than other types. The parts inside are built to handle very heavy work, so you can trust it in a busy factory. While other clutches may need replacing often, this one keeps going if you take care of it. That’s why many people choose this one, even when buying older machines.

From Factory Floor to eBay: Finding a Good Minster Brake Clutch

If you want to buy a minster cfc 3 disc 28 brake clutch, you can find it in many places. Some factories sell old machines with this clutch already inside. You can also find it on websites like eBay or online stores that sell used machine parts. But before you buy, make sure the part is not broken or too old. Look at the pictures and read what the seller says about it. If it says “used but working,” that’s okay—but ask questions to be sure. Check if the clutch was tested. You can also ask if they give any return option. Try to buy from sellers with good reviews. Even though it’s used, this clutch can still work for many years if in good shape. It’s like buying a used car engine—it needs checking, but it can be very useful.

Minster Clutch History: Why the CFC 3 Disc 28 Is Still a Good Choice

Minster has been making press machines for over 100 years, and the cfc 3 disc 28 brake clutch is one of their smart designs. This clutch was made long ago but is still used today because it works so well. Minster was the first to make many new things for press machines, like special clutches and quick stop brakes. The cfc 3 disc 28 came from years of learning and testing. It was made for safety, power, and easy care. Many companies trust this clutch because it helps their machines run smooth and fast. Even when new clutches come out, this one stays popular. That’s why it’s still a smart pick when buying or fixing a press. It has a strong name and a long history of helping factories work better.

Conclusion

The minster cfc 3 disc 28 brake clutch is a smart and strong part. It helps press machines work fast and stop safely. If you take care of it, it can last for many years and save you from big problems. Many old machines still use it today because it’s made very well. If you’re thinking about buying one, just check it carefully and ask the right questions.

I hope this blog helped you learn about this clutch in a simple way. Now you know what it does, how it works, and how to care for it. If you still have questions, don’t worry—that’s normal. Keep learning, and you’ll feel more confident when working with press machines or shopping for parts.

FAQs

Q: What is the minster cfc 3 disc 28 brake clutch used for?

A: It is used in press machines to help them start and stop safely during stamping work.

Q: Is the minster cfc 3 disc 28 brake clutch good for old machines?

A: Yes, it is strong and trusted for old machines that still work well.

Q: How can I check if the clutch is working?

A: Watch for smooth stopping, no noise, and no oil leaks from the machine.

Q: Can I fix the clutch if it breaks?

A: Yes, most parts can be replaced, and many people can repair it easily.

Q: Where can I buy a minster cfc 3 disc 28 brake clutch?

A: You can find it on websites like eBay, or from machine part sellers.